Serie GN-GNE-GNF-GNEF-GTB-GTBF-GNSN-GNSF-GND-GNED-GTBD-GNDF-GSV-GSVD-GTR-GPG

The choice of a flexible coupling depends on various factors, including:

Pay attention to:

Hub Length: Coupling hubs may have different lengths; verify their suitability based on the fastening system.

Holes: Shaft connection hole tolerances must adequate with the shaft tolerances.

Keyway: Keyway dimensions should match to avoid play that could damage parts.

Set Screws: Recommend inserting one or more set screws on the keyway to axially lock the half-coupling, at 45° or 90° angles. Various types of set screws are available; contact us to define the type.

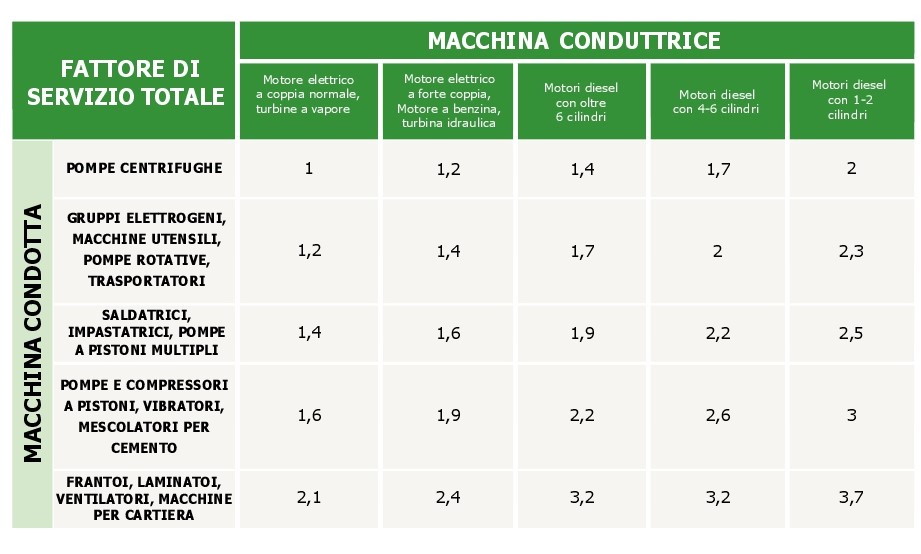

Select the coupling based on Tkn (nominal working torque), calculated using one of the two formulas below, depending on whether the power of the driving machine is expressed in kW or CV. Choose a coupling with a nominal torque higher than the resulting

Tkn from the calculation.

Tkn = RATED OPERATING TORQUE

P = CONUCTIVE MACHINE POWER

n= Rpm Conductive Machine

Fs = SERVICE FACTOR, which will be identified by the user, who may, at his discretion, consult the table below

Recommendations:

FOTOGALLERY

Criteria and recommendations for choosing the joint based on the application.

PRODUCTS IN THE SAME CATEGORY